Tests were performed to prove or disprove the efficiency of breathable membranes used in the roofing industry with the use of phenolic or rigid urethane boards. Knowing that phenolic or rigid urethane insulation boards are totally impervious (that is to say water or water vapour cannot pass from one face to the other) and that the use of such materials in the roofing industry are specified to be sealed and covered with a breathable membrane or breathable felt. Various tests and experiments where performed on these various types of these materials. It was found that breathable membranes/felts work when fitted over a counter batten placed above the phenolic or urethane insulation board.

The change of practice in the roofing industry with new materials and modern methods encouraged the construction of warm attics or loft spaces. As these attics or lofts are no longer ventilated they should be deemed as “confined spaces”, the warm moisture laden air or water vapour that enters the loft spaces from the dwelling will over time create problems as well as effecting indoor air quality. The material or members of the roof will absorb moisture, when these members are saturated damage will eventually result in the failing of the roof. As the phenolic or urethane insulation boards are virtually indestructible and not readily recyclable, roof’s that fail will result in a problem for landfill sites. A way was sought to alleviate this before problems started to arise. It was sought to remove the water vapour or moisture but ensure that the warmth or heat within the attic or loft was retained.

A test rig was constructed, a glass box with phenolic or rigid urethane insulation board sealed in place on the top. A counter batten was fixed and a breathable membrane/felt was fitted and sealed in place. A source of heat was used to achieve a constant temperature 20 degrees Centigrade in one instant, this was used to heat a reservoir of water to produce water vapour.

1.The amount of liquid was recorded at the beginning of the experiment.

2. Different types of ventilator where constructed using modern synthetic materials this passed through the insulation board under the breathable felt

3. Temperatures where recorded on the rig at intervals, different types of ventilator gave different results.

4. A ventilator was developed to achieve optimal results, to allow the water vapour to escape and cutting the amount of heat lost.

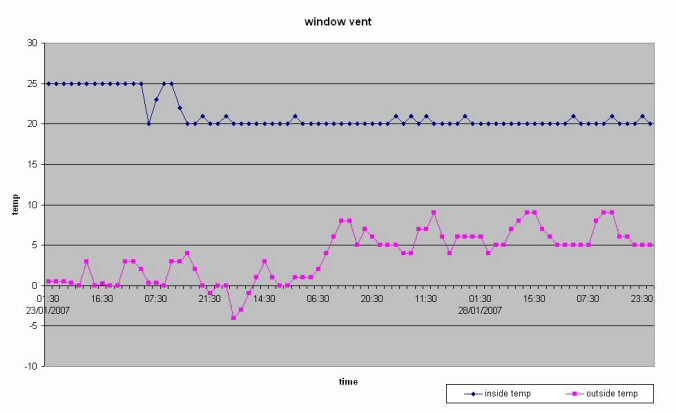

This first graph shows the temperatures recorded over a seven-day period the peaks in the outdoor temperature coincide with daylight or afternoon. The outdoor temperature was taken from the exterior side of the vent. It was also recorded that 390ml of water passed through this vent in the form of water vapour.

More results that have been recorded on other models of the vents

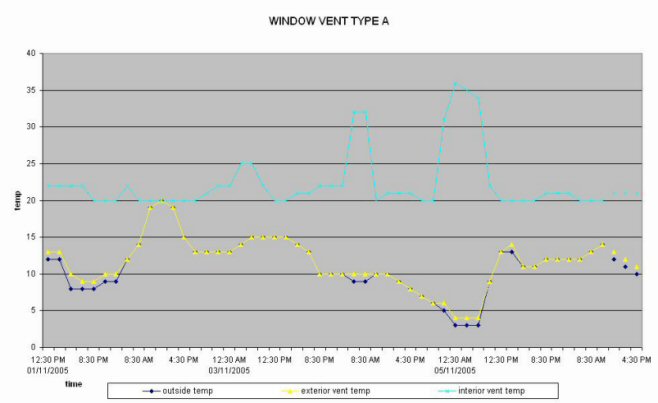

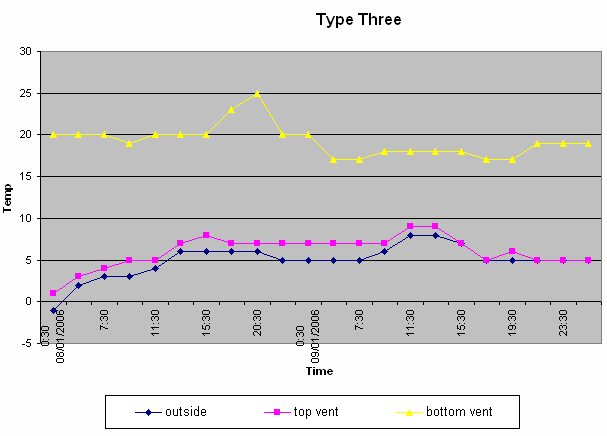

This graph shows the outside temperature as well as the temperature on the exterior side of the vent. The interior temperature fluctuates greatly but this has no effect on the the temperature on the external side of the vent.

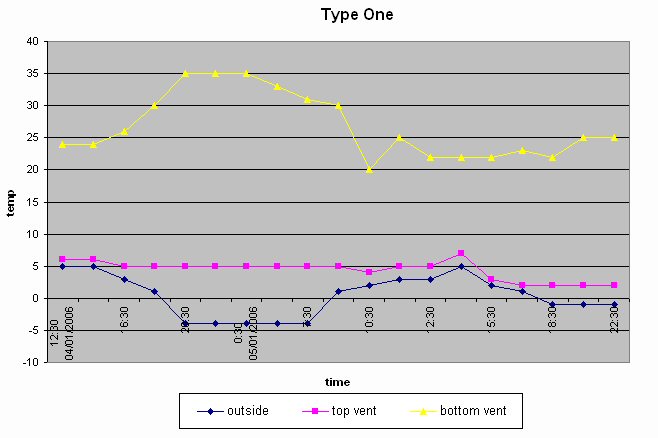

In this type 1 vent, the internal temperature fluctuates between 20 and 35 degrees but again it has little effect on the outside temperature of the vent. It should be noted that the temperature on the outside of the vent is greater than the outside temperature but it should also be noted that it does mimic the outside temperature with a two degree difference once the outside temperature rises above two degrees. This vent passed 360ml of water in water vapour in 37 hours.

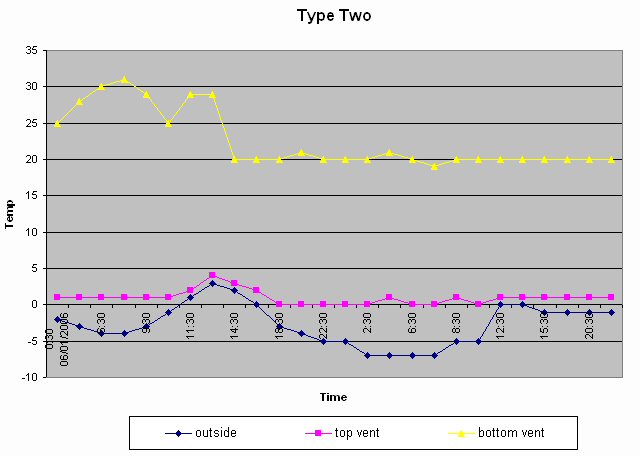

In this type two vent, the internal temperature fluctuates between 20 and 31 degrees again no effect is seen on the exterior of the vent. The temperature of the vent drops to zero but not below and again mimics the outside temperature with one degree of difference when the outside temperature rises above zero. This vent passed 180ml of water in water vapour in 45 hours.

This is the type 3 vent again the internal temperature varies with no effect on the external temperature of the vent. Again the temperature of the vent mimics the trend of the external temperature with a two-degree difference and then settles to follow the external temperature at about five degrees. This vent passed 95ml of water in water vapour in 49 hours.

The different models have similar characteristics and look identical but the heat retaining properties and the soundproofing qualities are different. This would allow us to make ventilation products to suit different areas and buildings with a variety of different problems. This would help buildings that face a busy road to have one model at the front and side of a building (to inhibit noise) and another model on the rooms that are not effected by noise pollution. Alternately rooms which produce a lot of moisture kitchens, bathrooms etc would benefit from the type one vent as this allows for a more rapid egress of moisture but still gives some sound proofing. It should be stated that all the vents help retain the internal temperature of the rooms where fitted.